A maritime worker’s life is no less than an adventure. They constantly need to stay alert to prevent any danger to the vessel. One area that is the most susceptible to fire and other damages is the ship’s engine room. Even though it is a crucial part of the vessel, it is also the one that faces extreme dangers. The multiple interconnected machines and systems in the engine room function ceaselessly to keep the vessel up and running. That being said, engine room accidents are some of the most common and dangerous mishaps that occur aboard a ship.

Common accidents aboard a ship in the engine room

According to the DNV, 2/3rds of the fires onboard ships start with the engine rooms due to minor mishaps. Accidents that occur here can quickly spread to other parts of the ship and are very challenging to deal with, as the engine room has an abundant supply of fire elements – Heat, Fuel, and Oxygen. An engine room fire can have destructive consequences and, in the aftermath, it’s unlikely for a ship to continue under her power.

In addition to fire, several common accidents occur in the engine room. Here are a few of them, along with measures on how to avoid them –

1. The explosion of the boiler

The boiler is high-pressure equipment, and any improper step while operating it can lead to an explosion. It is advisable to look out for fuel leakage inside the furnace. If the leakage is more and the boiler fires after an interval, it can cause blowback and even an explosion. Additionally, if the water circulation is not adequate, it can lead to heating of the boiler and cause an explosion.

Such an accident can be avoided by regularly maintaining the boiler and keeping it in a good condition. It can also prevent many fatal accidents and injuries. You should thoroughly check the machinery and equipment connected to the boiler. A malfunction in these can lead to a boiler explosion. Failure to properly perform pre and post-purging activities for boilers can also lead to an explosion due to the combustion of the unburnt residual fuel.

Although these incidents are not highly common, they can still be fatal due to related gas leaks and chemicals. You can oversee simple things like ensuring that a boiler never gets started from a cold condition, or cleaning of tubes can go a long way in maintaining the good health of the boiler.

2. High-pressure steam leakages

The engine room has several high-pressure steam lines running within. Accidents usually happen when these steam lines break or crack, causing the high-pressure steam to vent out instantly. It poses an immense danger as high-pressured steam is extremely dangerous to anyone present in the vicinity.

To avoid such cases, maintenance and regular checks are crucial. Failure of pipe joints in such pressurized steam pipes can also lead to fatal accidents.

3. Compressor airline explosion

Air compressors are highly pressured pieces of machinery and are one of the most critical parts of an engine room. The explosion of an air compressor occurs when the discharge valve is unopened while starting the compressor. These valves are generally closed to reduce air leakage, and not opening them again when necessary can cause an explosion.

Implementation of stringent checking protocols can help avoid these types of accidents.

4. Explosion in the engine’s crankcase

The part of the engine that houses the crankshaft is more prone to damage as it has all the prerequisites for an explosion – heat, lubrication, and air in the crankcase. The crankcase has several small particles which are inflammable when in contact with a hotspot.

As this is one of the most dangerous types of accidents, all the workers should be cautious and aware of this type of accident, to be trained to avoid it.

5. Scavenge fire

Certain areas of the vessel, specifically the engine room are places where the ignition can occur very easily due to the presence of air for combustion, fuel, and easy contact with heat. The instant flame up, known as the scavenge fire can occur due to these factors – Improper cylinder lubrication, uncleaned scavenge space, and broken or excessively worn-out piston rings.

There are many reasons for a scavenge fire. The common ones are listed below:

- Excessive wear of the liner

- The piston rings might be worn out or have loose ring grooves

- Broken piston rings or rings seized in the grooves

- Dirty scavenge space

- Poor combustion due to leaking fuel valves or improper timing

- Insufficient or excess cylinder lubrication

6. Over speeding of generator

Even though these types of accidents are rare, they are still harmful to both the crew onboard and the ship, as they can inflict heavy damage. When the ship’s generator starts, there are high chances that it will over-speed. As a precautionary measure, there is a presence of an over-speed trip. However, it could fail, leading to massive damage to the internal parts of the ship as they could get ejected or worn out. Loose parts being thrown out could also severely harm the crew members in the engine room.

7. Electrical shocks

Seafarers are always advised and trained to be prepared for electrical shocks through the right gear and equipment. The engine room houses cables and equipment of high voltage. One needs to be over-cautious during maintenance and should ensure they don’t initiate a machine accidentally.

Taking precautions through the right PPE is the best way to avoid electrical shocks, not just in the engine room but anywhere on the ship.

8. High-pressure fuel line bursting

According to reports, around 70% of all engine room fires are caused due to fuel leaks. A ship has multiple high pressurized lines and equipment that are prone to accidents. If there is a lack of proper maintenance of the pressure fuel line, it stands at a high risk of explosion. The fuel line supplies fuel to the combustion chamber and with the presence of high temperature and low maintenance, an explosion is a possibility. These explosions can cause fatal injuries to the crew.

Additionally, if the lines are not rightly secured, it can cause continuous friction and vibration, leading to an explosion.

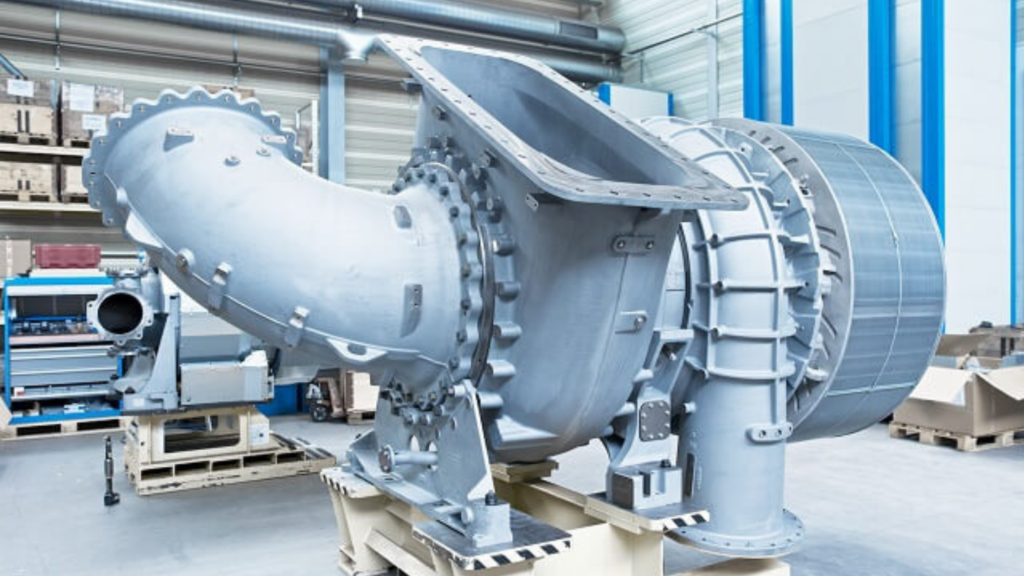

9. Turbocharger explosion

A turbocharger explosion occurs when the turbocharger is not maintained and cleaned for a prolonged duration. In the case of unkept turbochargers, carbon deposits could come in way of the cooling process. Further through the cracks, the oil that gets into the exhaust side of the turbocharger with the parts already being heated in the presence of a fuel source, makes it prone to explosions.

How to Prevent an Engine Room Fire?

Now that we have understood several causes of fire in the engine room, it is also important for us to understand how to prevent it. Here are a few preventative methods that can be life-saving in cases of emergencies –

Locate the heat sources

A heat source is a source of ignition is where one needs to be cautious. Improper use of welding and electrical equipment can also become a source of ignition.

Raise a proper alarm

As soon as a fire or an engine room accident occurs, it is essential to alert all those on board and carry out the necessary protocol to contain and eventually put out the fire.

Fight fire by conventional means

Train the ship’s personnel to fight fire with standard pieces of equipment like hand-held fire extinguishers, fire pumps, fire hoses, and large capacity extinguishers to minimize the fire spread.

Ensure that the engine room has proper casing

Most engine rooms and decks are made with steel to limit the spread of the fire.

Keep the engine room clean

Maintain high standards for cleanliness in the engine room to prevent fires. You can also avoid bringing combustible and flammable material into the engine room.

In addition to the above main preventative measures, you should also follow the overall maintenance guidelines on board a ship. You can conduct timely repairs on pipes and leakages, close valves on time, and ensure that proper engine alarm systems are installed, and are in functional condition.

Companies need to be serious about responsible leadership roles to ensure that seafarers are provided with the right equipment and gear. It can help minimize the adverse impact of engine room accidents on the crew. Other than that, companies should also provide adequate training to the crew to be precautious and to handle a situation of crisis. Establishing the right chain of accountability and imparting good communication to the crew can minimize the incidents of engine room accidents tremendously.

Engine room accidents and fires are some of the worst mishaps that can occur at any point in a seafarer’s life. Therefore, it is essential to promote safety awareness and train the crew to prevent fires and other potential hazards. Such simple steps can also help in saving the lives of many people.

Engine room accidents can be prevented most of the times, by taking the right precautions, carrying out timely maintenance and conducting all the safety checks from time to time. But, mishaps due to human error cannot be ruled out completely.

SHM’s Safety Equipment and Services have got you covered for every kind of accident that might take place aboard a ship.

- For Fixed Fire Safety Equipment to be installed aboard, click here.

- For Firesuits and Breathing Devices, click here.

- Check our range of Fire Extinguishers, here.

- For lifesaving appliances, in case of ship abandonment scenarios, click here.

- For end to end Fire Fighting Services and maintenance of the Fire Fighting equipment aboard, click here.

To find your nearest SHM Group branch, visit us at www.shmgroup.com.