Regular boat maintenance is the key factor that affects the efficiency, functioning and durability of a boat. Over the last few years, FRP boats have become much preferred to other widely used boats. Due to their versatility, durability and ability to resist corrosion, they are more affordable for prolonged use. The government of India has encouraged using FRP boats due to their environment-friendly features like less fuel consumption.

However, before you use these boats, it is essential to know their basics and maintenance.

What are FRP boats?

Fibre Reinforced Plastic (FRP) is an alternative material for steel and other metals in boat building. It is a composite material of a polymer matrix, toughened with fibres like glass, carbon, aramid, or basalt.

FRP is popular due to its mechanical strength and properties like temperature resistance, corrosion, chemical resistance, and thermal insulation. FRP is also lightweight, durable, fuel-efficient and relatively cost-effective compared to other boat-building materials. It is also highly customisable and can suit a variety of requirements.

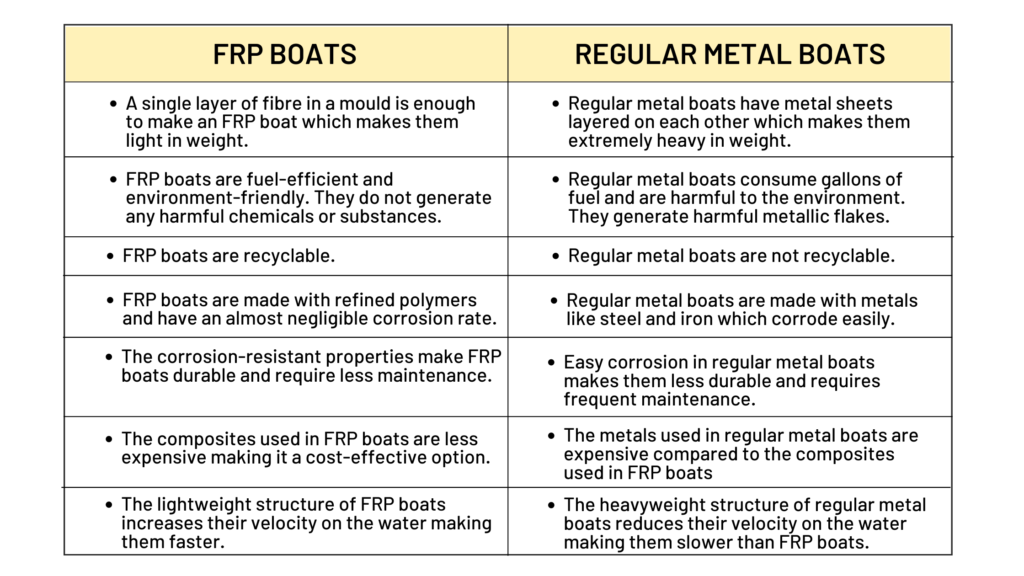

FRP Boats vs Other Boats – What is the Difference?

Need for FRP Boat Maintenance

Even though FRP boats are low maintenance, they can only remain in good shape if appropriately maintained. FRP boats should be regularly cleaned, polished, and waxed to protect the gel coat on the surface vessels and make the hulls look brighter. Painting its surface layer can also keep its appearance and durability intact.

IMO and SOLAS standards

The IMO issued amendments in January 2020 for the maintenance of lifeboats through regular examination, operational testing, overhaul and repair, and launching appliances and release gear. These provisions aim to prevent accidents and ensure the equipment’s maintenance and safety standards.

SOLAS Amendments for Lifeboats

- Requirement for Examination

The equipment requirements include lifeboats (including free-fall lifeboats), fast rescue boats, davit-launched life rafts, launching appliances, and on-load and off-load release gear for lifeboats.

- Operational Testing, Repairs, and Overhauling

It is essential to carry out weekly and monthly inspections, routine maintenance, thorough annual examinations, and operational tests. You must also conduct a five-year thorough examination, overhauling, overload operation tests, and equipment repairs. All testing and examination are to be done by certified personnel of the manufacturer or authorised service provider under the direction of the ship’s senior officer.

- Approved Bright Orange Colour and Designs

The lifeboats must also sport an internationally approved bright orange, with the ship’s call sign printed.

- Survival Equipment Inside the Boat

t is also essential to carry survival equipment, including freshwater, compass, distress signalling equipment, food and ration in a lifeboat. The lifeboats and liferafts should accommodate at least 125% of the number of passengers and crew on board.

- Authorisation by Certified Personnel

The flag administration must authorise the service providers following Sections 3 and 7 of Resolution MSC.402(96). Every authorised service provider must issue a certification for their personnel for the make and type of equipment to work on and the specific activities.

Preventive Maintenance Services

Preventative maintenance services ensure that the boat’s engine runs longer. Every manufacturer has specific recommendations regarding boat maintenance. It is advisable to take a look at those recommendations before performing maintenance.

- Periodic Inspections of Propeller and Engine

Check for loose belts, cracked hoses, and corrosion on the engine and replace or repair it immediately if found. As the propeller plays a vital role in determining fuel consumption and performance, ensure that the propeller nut is tight and look for any damage that can lead to fuel burning. Grease the shaft by removing the propeller and ensure that there is nothing wrapped or stuck around it.

- Oil Changing

Change the oil regularly to ensure that the mechanical parts slide smoothly and perfectly against each other. If not changed regularly, it can solidify or become acidic and cause severe damage to the internal components of the engine. Follow the manufacturer’s recommendations for an oil change and set a fixed schedule for oil changing.

- Hull Fittings

Check the hull fittings for cracks, blisters, leakage, and corrosion. Ensure that the drain plugs are in place, that the valves are operational, and can be easily opened or closed. Replace or repair them immediately if required.

- Belts or Hoses

Continuous exposure to vibrations, high heat, and hard knocks can loosen the belts and hoses and lead to equipment failure. Check the belts and hoses, and repair them whenever necessary to ensure optimum engine performance.

- Leak checks

Always check for oil and water leaks before leaving the dock. Check the fuel lines for any cracks and soft spots. Watch out for any stains or smells of fuel around the fittings. Undetected and unsupervised leaks can lead to the failure of vital components. Ensure that these leaks are detected and repaired immediately.

- Impellers and Pumps

Inspect the impellers and pumps to detect any failure. Failure in the impeller leads to the dysfunction of the water pump. As a result, its ability to pull water reduces and the engine overheats. Ensure that the impellers never run dry and that the pumps move at a sufficient speed. .

- Corrosion control

Clean the boat’s engine with fresh water after operating it in salt water. The freshwater helps in removing salt residue and protects the finish. Salt deposition on the metal components of the boat or ship can lead to corrosion, especially on the lower units.

Corrective Maintenance Services

Corrective maintenance measures target the causes of the problems by implementing necessary remedies and solutions required to ensure the proper functioning of the boats. Corrective maintenance helps identify and rectify the problems. The process of corrective maintenance is time-consuming compared to preventative maintenance as it involves extensive inspection of the components by an authorised professional.

- Refurbishments

Refurbishments can make the existing vessels more efficient and cost-effective, and can improve the towing power. It also helps comply with new legislation and regulations. Recently, SHM Shipcare refurbished Taklift 7, a Davit suspended FRP rescue boat manufactured in 1977. The boat had multiple cracks and extensive damage. The boat was refurbished to its original form by performing the desired fitness tests as per the SOLAS guidelines and was then declared sea-worthy within 3 weeks.

- FRP Lamination and Build-up

FRP laminates have multi-layered sheets that have a single or a two-directional resistance. They are bonded together to concrete or steel surfaces using FRP epoxy resin systems. It offers resistance to corrosion and ease of handling. Installing these laminates makes it easy to clean the build-up.

- Gelcoat Repair and Rebuffing

Regular use of the boat can cause damage to the gel coat. The gel coat maintains the finish and the lustre of the vessel in good condition. Gel coat repair and rebuffing can help eliminate the scratches, oxidation, chips, minor cracks, and small patches on the surface.

- Anti-fouling and Painting

Anti-fouling paints prevent sea life, such as algae, from attaching itself to the hull, which causes the slowing down of the engine and increases fuel consumption. The paints protect the bottom of the boat. SHM also offers marine paints and accessories which include epoxy, polyurethane and thinners, underwater and anti-fouling coats, airless spray machines and sprays and much more.

- Monsoon Dry Docking Services and Storage

Dry docking of boats is beneficial in saving the boat hull and drives, especially during monsoons. It also gives easier access to boarding, fueling, and maintenance. Dry docking helps avoid scrapes and bruises caused by excessive bouncing when tied to a wet dock.

- Furniture Repair and Carpentry Work

The interiors and exteriors of a boat must be able to withstand severe weather conditions such as harsh winds, humidity, and saltwater. Furniture repair and carpentry work in boats need a skilled marine carpenter who can use the proper techniques and tools to give the desired result. Hiring a marine carpenter who can offer sturdy and resilient repairs is essential.

The Taklift 7 showcased extensive damage including multiple cracks and abrasion making it unfit for usage. The services rendered included OEMs, painting, boat metrology and overall maintenance.

- Engine, Water Jet Service, and Overhauling

It requires trained engineers to carry out the servicing of engines and water jets. The machines must be handled with ease during such overhauls. It includes oil changes, filter renewals, essential engine health checkups, repairing impellers, hydraulic actuator adjustments, and much more.

- Deck Fitting and Upholstery Work

These services include the repair work and the maintenance of the basic design and construction of the boat. It requires a skilled and experienced professional who ensures the fittings and repairs are done correctly and efficiently without causing any new damage.

- Stainless Steel Fabrication

Marine-grade stainless steel offers the highest level of corrosion resistance and toughness. It is resistant to the effects of salt water and other harsh elements, which cause rusting and corrosion.

- Electrical and Mechanical Repairs

Electrical repairs include checking wire and cable fittings, repairing blown fuses, and checking motors and blowers. Mechanical repairs include installation, maintenance, and up-gradation of motor work and equipment fixes.

- Trailer/Cradle Manufacture and Repairs

Trailers and cradles are vital in towing, storing, or upholding boats. They need to be sturdy to ensure the proper functioning and hence require professional intervention for manufacturing, maintenance and repairing.

- Design and Mould Making

The design and mouldings play a vital role in boat building. It requires skilled personnel, high-quality materials, and sufficient labour to create designs for the interiors and the systems based on the requirements.

- Lab Tests of FRP Laminate Panels

The FRP laminate panel can get damaged after long-term and extensive usage. Laboratory testing helps identify the materials’ defects or the panels’ manufacturing. These defects can further get repaired to maintain the quality.

Endnote

There is a substantial growth in the use and manufacturing of FRP boats. They are cost-effective, fuel-efficient, and low maintenance, causing their advantages to outweigh the disadvantages. SHM Shipcare specialises in repairing, maintaining, and dry-docking FRP boats, tanks, storage cabinets, and hatches.

As mentioned earlier, SHM Shipcare can provide all of the maintenance services with the highest quality of materials and expertise.

Get in touch or send an enquiry to know more about our FRP boat repair and dry-docking services.