Inflatable boats are lightweight boats that are constructed using flexible tubes containing pressurized gas. These boats are convenient for transport in case of emergencies or short distance manoeuvering.

In addition, inflatable boats are compact and deflating for efficient storage and transformation. Hence, they are often used as life rafts for ships and airplanes or recreational purposes.

Over the years, leading to the development of the modern inflatable boats, numerous upgrades have been made in the appearance and fabric used to build them. The modern-day inflatable boats are versatile, the most popular among them being Rigid Inflatable boats and Soft Inflatable Boats.

- The RIB or Rigid Inflatable Boat is a developed inflatable which boat is made up of a rigid flooring and hull. This boat has a strong endurance during extreme weather and rough currents.

- The SIB or Soft Inflatable Boat has a low draft and lacks the structural rigidity of the RIB. Due to the absence of any rigid material in its structure, the SIB is foldable and very compact, making it extremely convenient for transportation and usage.

Inflatable boats span up to 2 to 7 meters in length and are propelled by motors of 1.7 to 223.7 kW. They are extremely popular and easy to use due to their compact size, convenience, speed and mobility.

Inflatable boats are used in rescue operations or for short distance travels. They have been increasingly used for scuba diving excursions, kayaking and other recreational purposes. A range of inflatable boats is available including rubber rafts, inflatable kayaks, lifeboats, and rescue boats.

There are several leading boat manufacturers in India that design and manufacture inflatable boats, SHM Shipcare is one of them. Let us now take a look at the types of inflatable boats that Shipcare manufactures. Boats Available with SHM Shipcare

SHM Shipcare places a strong emphasis on the creation of a safe and secure environment at sea and hence offers a comprehensive set of products and services for the same. The company also provides maritime safety solutions and launching-appliance services. The different types of boats that SHM Shipcare provides are as follows:

-

Rigid Inflatable Boat:

- The RIB manufactured by SHM is lightweight and high performing boat.

- Specs: L: 7.4m/4.7m, GRT: 2.8 tons.

- It has a crew capacity of 3 pax and a hoisting capacity of 5 pax.

- Its full load capacity is 18 pax.

- The top speed is 32 knots.

- This boat is used in various applications including rescue, patrolling, interceptions and as tenders for ships

-

Safin 420 Inflatable Rescue Boat:

- The Safin 420 is India’s first to be awarded the EC/MED certification. This boat is constructed using UV resistant fabric and is lightweight.

- Specs: L: 4.2m, W: 1.8m, Colour: Orange

- It has a full load capacity of 6 pax, which includes 5+1 stretcher.

- It is made of Hypalon Neoprene.

- The boat exerts excellent endurance capacity with weather, puncture, and abrasion resistance.

- In addition, the boat assures durability with optimum performance.

-

Gemini Boat:

- The Gemini is a compact and easy to use boat which can be launched from any major type of vessel. It is lightweight and highly durable.

- Specs: L: 4.4m, W: 1.8m, Colour: Light Grey.

- It has a full load capacity of 10 pax.

- It is made of Hypalon Neoprene.

- The Gemini boat consists of numerous accessories that are accessible in rescue operations. These include bellow pump, boat hook, repair kit, lifting sling, spare valves and paddles.

- The Gemini boat consists of numerous accessories that are accessible in rescue operations. These include bellow pump, boat hook, repair kit, lifting sling, spare valves and paddles.

- The Gemini Boat is India’s first boat to be approved by the international classification society RINA. It is also the first to comply with the new NCD specifications.

Manufacturing these boats involves making use of different materials and fabrics based on the purpose for which they are being used. Let us take a look at the same.

Types of Fabrics used for Making Inflatable Boats

Inflatable boats were mostly made with rubber for a long time. However, nowadays, most of the boats are made of plastic polymers like PVC (polyvinyl chloride fabric). New materials, such as Hypalon or Neoprene are synthetic rubbers that are gaining momentum due to higher resistance and efficiency. Here, we see some of the popular materials being used for manufacturing inflatable boats.

-

PVC fabric

PVC is a vinyl polymer chemically known as polyvinyl chloride. It is a type of plastic that can be thermo-bonded or glued onto polyester or nylon.

- PVC fabrics are the popular fabrics owing to their strength, elasticity, resistance.

- It is also easier to repair and has a higher resistance to ultraviolet rays.

- It has absolute water and sufficient chemical resistance.

- PVC is also a largely affordable and cost-efficient option as opposed to other fabric options.

- It is available in a wide array of colour options.

-

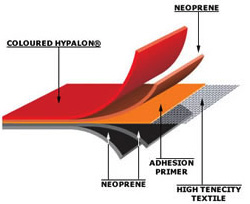

Hypalon or Neoprene fabric

Hypalon is a synthetic rubber material and has many applications in the marine industry.

- It is a material with an excellent capacity for holding air, which makes it a great option for inflatable boats.

- It is oil resistant.

- It can be coated on polyester or nylon fabric in addition to an interior coating of neoprene. It has proved to be a very reliable and durable type of fabric.

- Hypalon fabric lasts for over a decade and endures the harsh weather conditions.

- Since Hypalon has greater strength and durability, inflatable boats made out of this fabric are more expensive.

To construct an inflatable boat, it is necessary to have a proper design, construction, and engineering to ensure a proper structure. However, the structure of the inflatable boat depends on the building material. Materials used to construct an inflatable boat play a crucial role since these boats don’t have much of a frame. It depends on the fabric to endure and carry the load of the structure.

Due to these reasons, SHM uses Hypalon or Neoprene fabric in the construction of its inflatable boats. Here are a few advantages of Hypalon over other materials.

Advantages of Hypalon

- Hypalon has a higher resistance to ultraviolet rays and chemicals. Hence, it has been proven to be the most durable option for inflatable fabrics.

- It can withstand temperatures from -50 to +80 degrees.

- Hypalon is most commonly used to make inflatable boats and foldable kayaks. It also has better temperature endurance.

A common question people have is, why is Hypalon better than PVC? Well, here’s why.

Why Hypalon is better than PVC?

- Hypalon is better at withstanding the deteriorating effects of extreme temperatures, oxygen, weather, oil and chemicals.

- Hypalon has excellent resistance to abrasion as opposed to PVC, which is not resistant once it dries.

- It remains largely unaffected by extreme weather conditions and does not deteriorate or get brittle over time. PVC, on the other hand, does not respond well to extreme climate and temperatures.

- Hypalon is highly resistant to chemicals. So, an inflatable boat made of Hypalon will be much less affected in the case of an oil spill or a fuel spill, while PVC is not resistant to the deteriorating effects of chemicals.

- Inflatable Hypalon boats will not deteriorate with time and these boats will be extremely durable, with a span of at least a decade. PVC-made inflatable boats have a shorter life span and deteriorate quickly.

- It is much easier to repair a Hypalon inflatable boat. By just applying a patch on the field, an inflatable boat made with Hypalon is quickly repaired. It is much harder to repair a boat made out of PVC due to its fragility.

Hence, Hypalon fabric is the more suitable choice of fabric for inflatable boats as compared to PVC.

Regardless of the material used to build an inflatable boat, it is necessary to carry out routine maintenance and repairs and ensure proper care of the boat. Here are a few tips and services.

Rigid and Inflatable Boat Services Available with SHM

Inflatable boats need appropriate care and timely maintenance to ensure durability. It isn’t advisable to keep your boat in the direct sunlight. The boats also need to be folded carefully and a layer of protectant chemical should be applied before they are kept away.

SHM Shipcare provides a range of services for the maintenance of Rigid and Inflatable Boats. These include:

-

Periodic Boat Inspection and Services

In accordance with regulations of IMO, all inflatable boats and rigid boats should be subjected to annual and 5 yearly maintenance and inspection regularly. Additional pressure tests of these boats are to be taken as per manufacturer’s guidelines.

-

Rescue Boat launch test

Inflatable rescue boats are to be tested and launched during the annual inspections to check if the lifting slings and release hooks are in working condition.

-

Release Hook Inspection

The release hook of the rescue boat is tested during an annual inspection. These hooks are to be overhauled by the manufacturer during the regular 5 yearly routines.

-

Dynamic Winch Brake test

To ensure if all the equipment is serviced properly, the winch brake is dynamically tested by lowering the rescue boat.

-

Single Arm Davit Winch Inspection

Servicing of rescue boat slewing davit is to be done during the annual inspection routine.

-

Pressure test at the service station

Inflation and pressure test of an inflatable boat is conducted routinely at service stations.

Endnote

Inflatable boats are extremely convenient to use and have an important role to play in rescue operations. They are mostly used as lifeboats and rescue boats. Hence, the inflatable boat must be of the utmost quality and durability, to efficiently carry out tasks.

Inflatable boats made of PVC and Hypalon are the two most common and easily available options of fabric. SHM Shipcare uses Hypalon to make inflatable boats due to its durability and strength of Hypalon. Inflatable boats are used as lifeboats on big vessels. Inflatable boats are the most important aspects of marine safety.

What are your thoughts about applications of inflatable boats? Any experiences you would like to share? Drop a comment to let us know!